When you need specialized flooring for your clean rooms, here at DBS we have the perfect solution for you with our Aluminum Raised Access Floor panels.

Our Aluminum access floor from Seo Kyung and Hae Kwang undergoes strict quality control to meet electrostatic or conductivity requirements. Each panel is carefully checked to eliminate any potential contaminants including adhesive residues. Allowing easy access to piping and electrical wiring that run under cleanroom floors, our aluminum panels will provide the benefits of raised access flooring while sustaining a super clean environment.

Standard: Perforated panels have a nominal open-air ratio ranging from

14-26% to meet specific airflow requirements inside cleanrooms.

High-output panels: Grating panels have a nominal open-air ratio ranging from 26-55% facilitating unrestricted smooth airflow and minimizing vibration from rolling loads.

DBS offers the FreeAxez Steel Gridd cable management system that is a great solution for keeping your cables clean, organized, and accessible, running in your floor rather than in the ceiling.

Gridd is a whole building design approach that integrates cable distribution technology throughout the entire building infrastructure. The modern office needs to organize a tremendous number of cables and wires to accommodate computer networks, telephones and general power requirements. We offer Gridd solution to create organized and efficient access to your cables, making your spaces flexible and easy to rearrange.

At DBS, we offer various finishes for rooms with equipment sensitive to static electricity. These finishes generally come in three different categories: Antistatic, static dissipative and conductive. They all are available with a large variety of finishes and materials to suit your space and preference; carpet (also available as PosiTile, the 1-to-1 fit to the access floor), High Pressure Laminate (HPL), Luxury Vinyl Tile (LVT), rubber, vinyl tile, etc.

Antistatic flooring should be installed in high traffic/high use networked environments to minimize nuisance static and to provide additional protection against static damage. ESD flooring should be installed anywhere the threat of uncontrolled static electricity buildup and discharge is a concern and could jeopardize the performance and operation of electronics systems or the handling, assembly, and repair of electronics. Conductive flooring should be installed in spaces where there are demands of low electrical resistance through the floor.

We can also supply floor finishes contributing to LEED points and LEED certification for your building. Contact us for more information.

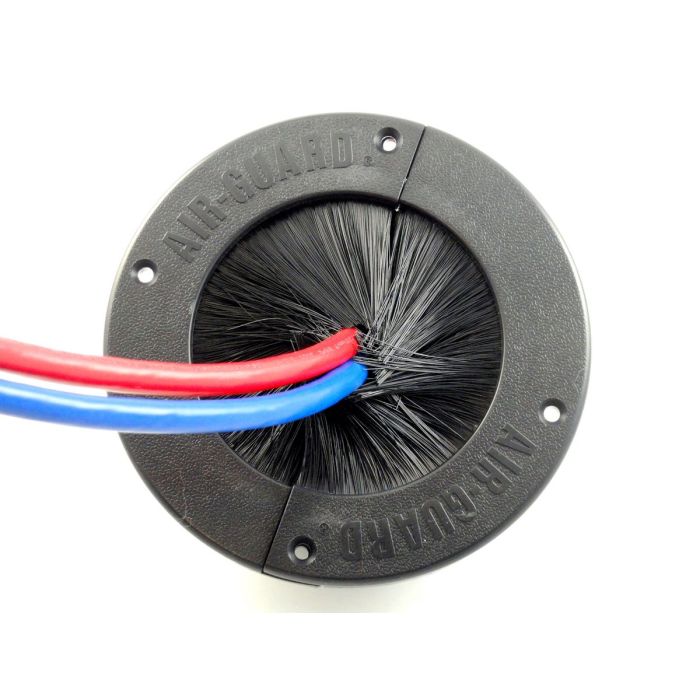

DBS offer AirGuard air sealing grommets, minimizing leakage from underfloor air plenums.

A round insert that can be dropped into a hole cut into an access floor panel. Used to protect the wiring insulation and the technician’s hand from being cut by sharp edges created when a panel is cut, it provides a pathway from beneath the access floor to allow for wiring equipment. Provided with a cover to prevent debris from falling through to the subfloor cavity. Typically black in color, available in several diameters ranging from 1.78″ to 8″. Sometimes called holios, sleeves, ports, trim, flange, and round molding. The split grommets allow product installation or removal without disturbing existing cables.

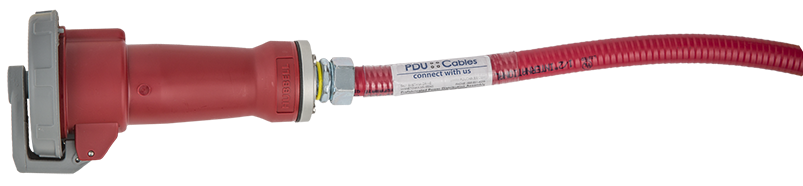

PDU cabling and connectors are designed specifically for access and underfloor

applications.

A PDU Cable, branch circuit power distribution cable or “power whip” is a cable that carries power from a Power Distribution Unit (PDU) or Remote Power Panel (RPP) underneath a raised floor to power equipment in server rooms etc.

PDU Cables can be found in almost any environment that has a raised floor.

DBS offers Rittal Enclosures/Cabinets for innovative enclosure and housing technology for server rooms etc.

When considering safety and design flexibility, Rittal’s power isolation enclosure solution provides the capability to separate high and low voltage equipment, supporting compliance with NFPA 70E workplace safety standards.

(925) 254-3454

239 Glorietta Blvd. Orinda CA 94563

info@DynamicBuildingSystemsInc.com

(702) 367-3336

8275 S. Eastern Ave. Ste 200

Las Vegas NV 89123

When considering safety and design flexibility, Rittal’s power isolation enclosure solution provides the capability to separate high and low voltage equipment, supporting compliance with NFPA 70E workplace safety standards.

PDU Cables can be found in almost any environment that has a raised floor.

A PDU Cable, branch circuit power distribution cable or “power whip” is a cable that carries power from a Power Distribution Unit (PDU) or Remote Power Panel (RPP) underneath a raised floor to power equipment in server rooms etc.

PDU cabling and connectors are designed specifically for access and underfloor applications.

A round insert that can be dropped into a hole cut into an access floor panel. Used to protect the wiring insulation and the technician’s hand from being cut by sharp edges created when a panel is cut, it provides a pathway from beneath the access floor to allow for wiring equipment. Provided with a cover to prevent debris from falling through to the subfloor cavity. Typically black in color, available in several diameters ranging from 1.78″ to 8″. Sometimes called holios, sleeves, ports, trim, flange, and round molding. The split grommets allow product installation or removal without disturbing existing cables.

Antistatic flooring should be installed in high traffic/high use networked environments to minimize nuisance static and to provide additional protection against static damage. ESD flooring should be installed anywhere the threat of uncontrolled static electricity buildup and discharge is a concern and could jeopardize the performance and operation of electronics systems or the handling, assembly, and repair of electronics. Conductive flooring should be installed in spaces where there are demands of low electrical resistance through the floor.

We can also supply floor finishes contributing to LEED points and LEED certification for your building. Contact us for more information.

Gridd is a whole building design approach that integrates cable distribution technology throughout the entire building infrastructure. The modern office needs to organize a tremendous number of cables and wires to accommodate computer networks, telephones and general power requirements. We offer Gridd solution to create organized and efficient access to your cables, making your spaces flexible and easy to rearrange.

DBS offers the FreeAxez Steel Gridd cable management system that is a great solution for keeping your cables clean, organized, and accessible, running in your floor rather than in the ceiling.

Standard: Perforated panels have a nominal open-air ratio ranging from

14-26% to meet specific airflow requirements inside cleanrooms.

High-output panels: Grating panels have a nominal open-air ratio ranging from 26-55% facilitating unrestricted smooth airflow and minimizing vibration from rolling loads.

Our Aluminum access floor from Seo Kyung and Hae Kwang undergoes strict quality control to meet electrostatic or conductivity requirements. Each panel is carefully checked to eliminate any potential contaminants including adhesive residues. Allowing easy access to piping and electrical wiring that run under cleanroom floors, our aluminum panels will provide the benefits of raised access flooring while sustaining a super clean environment.